Thankyou Carol for letting me know you are reading it and like it. In these stages a lot of the pictures are boring to some - until they decide to do something similar and then you wish there were more pictures (at least I did). Thank you though very much for the comment.

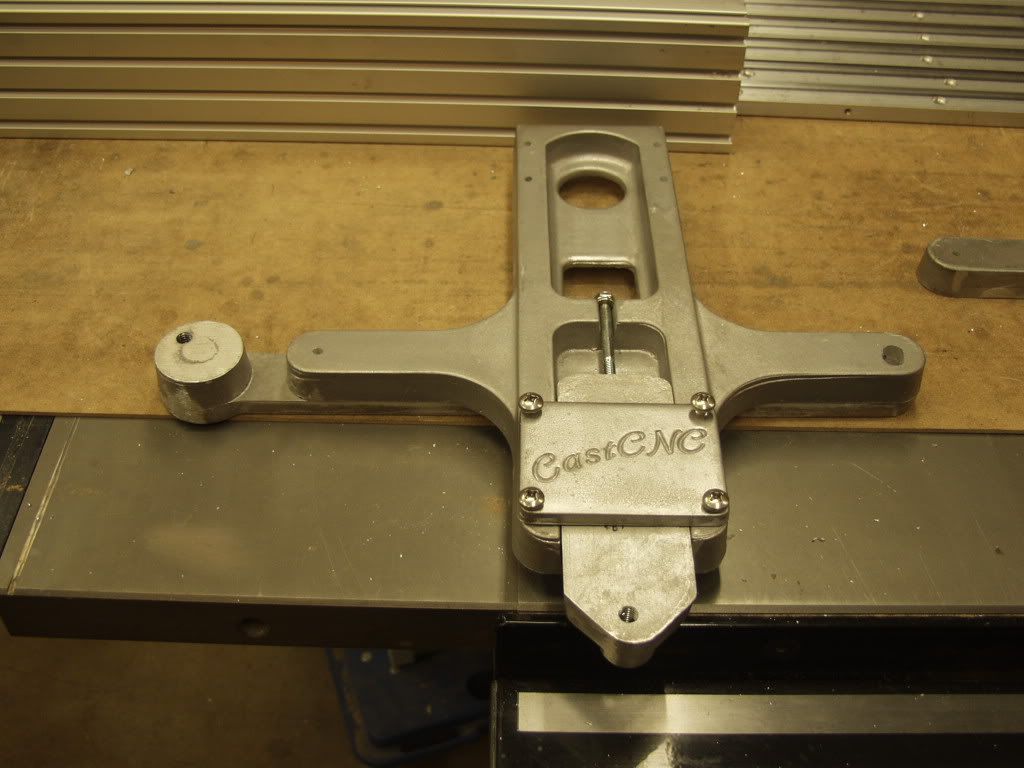

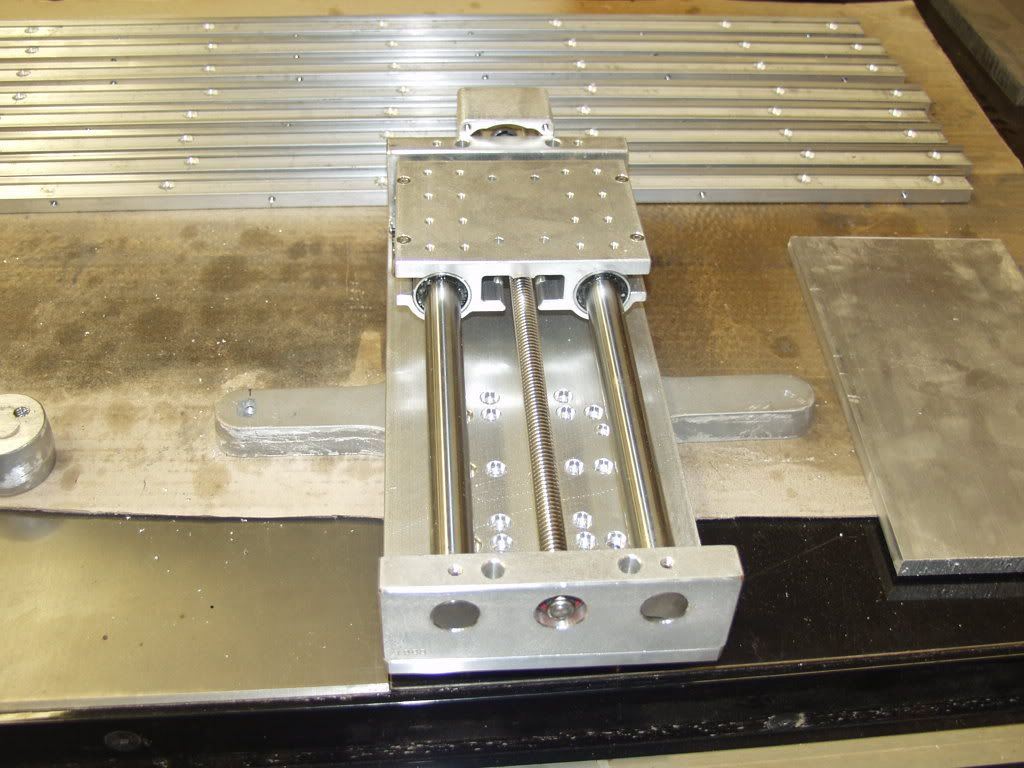

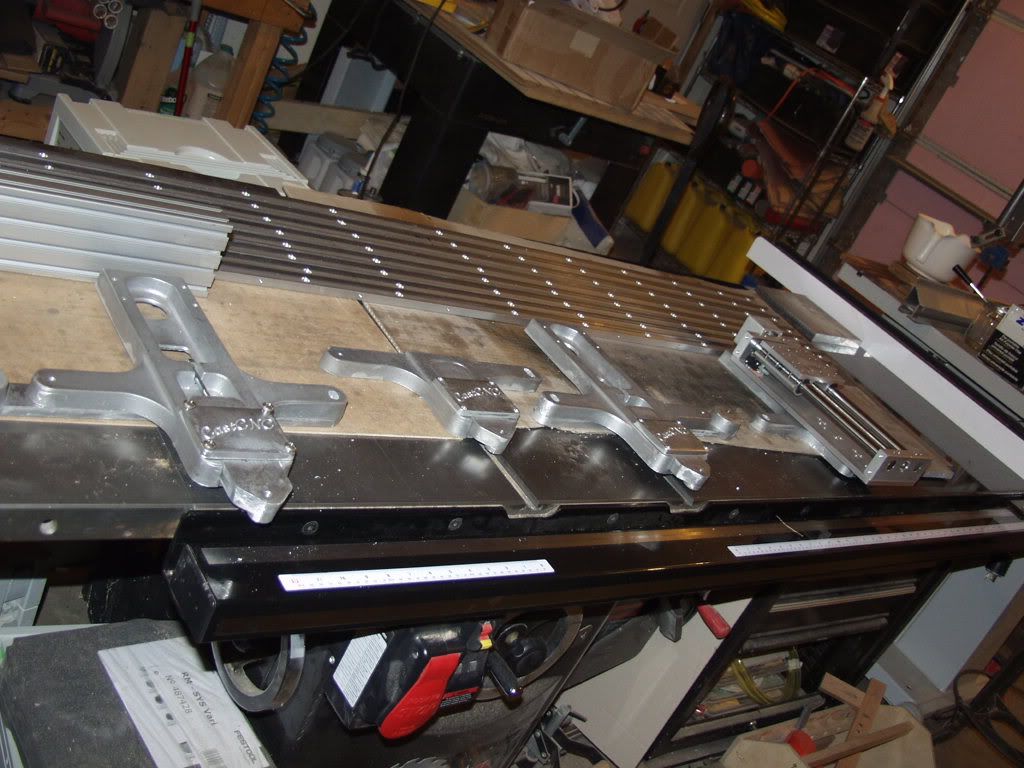

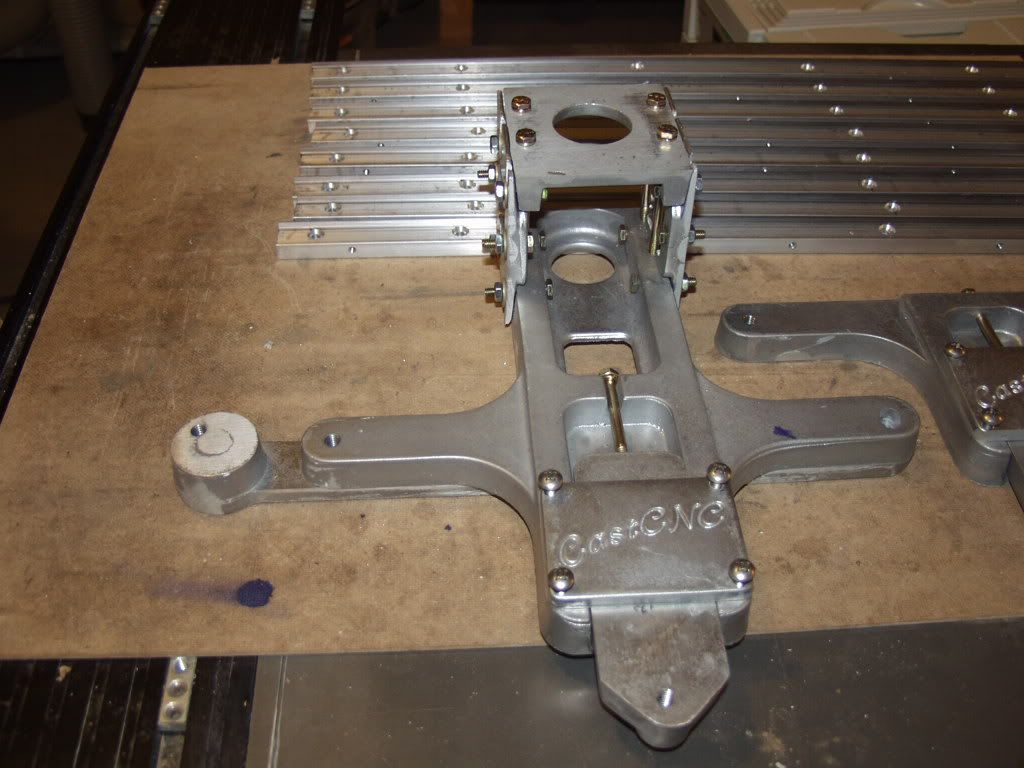

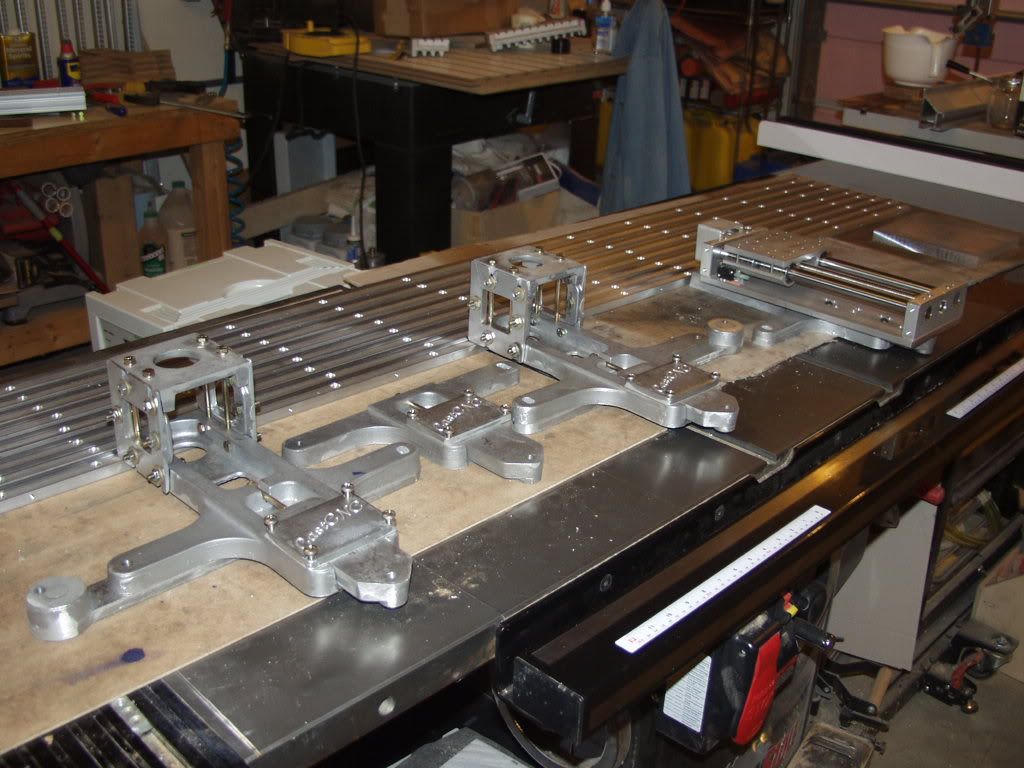

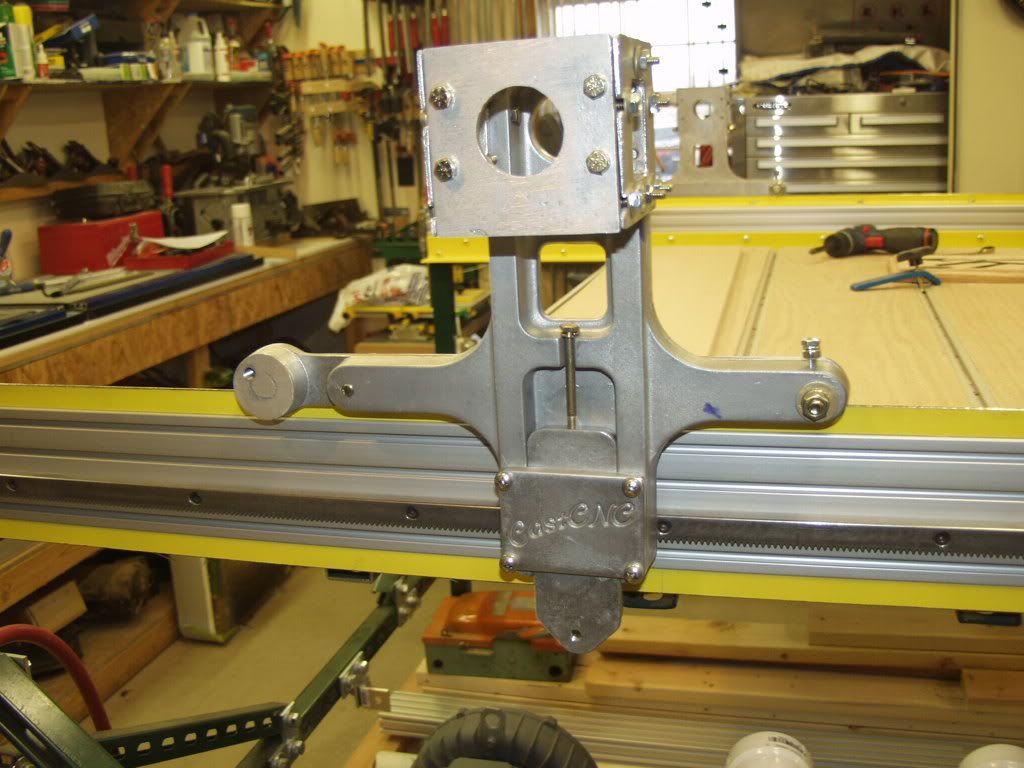

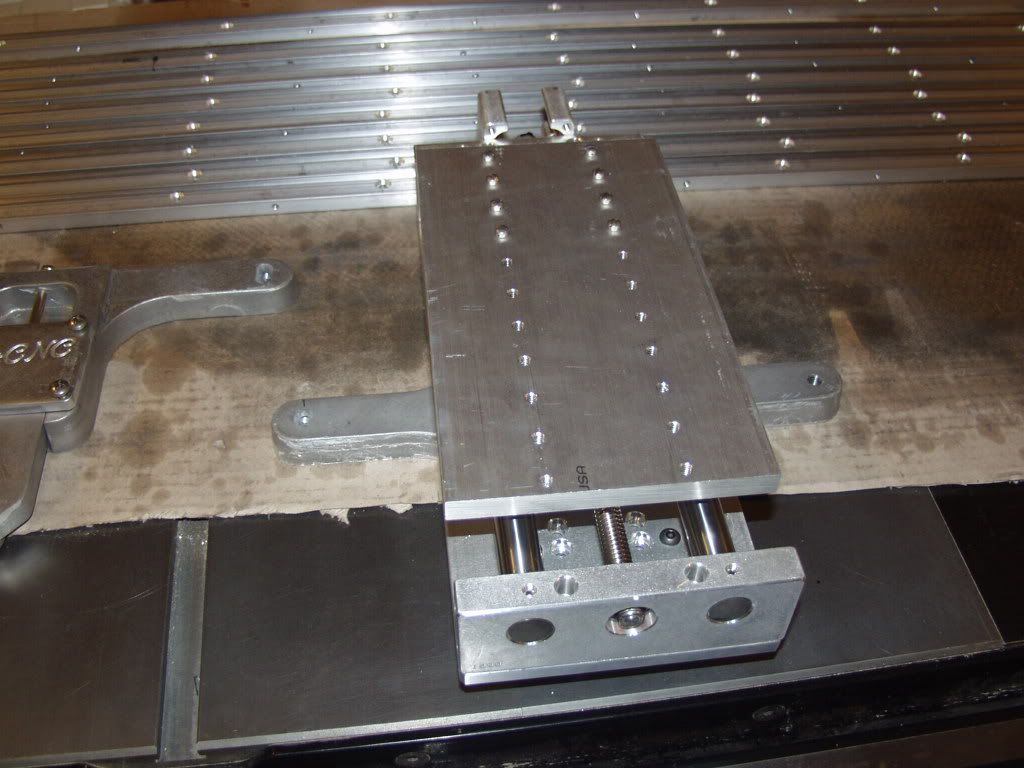

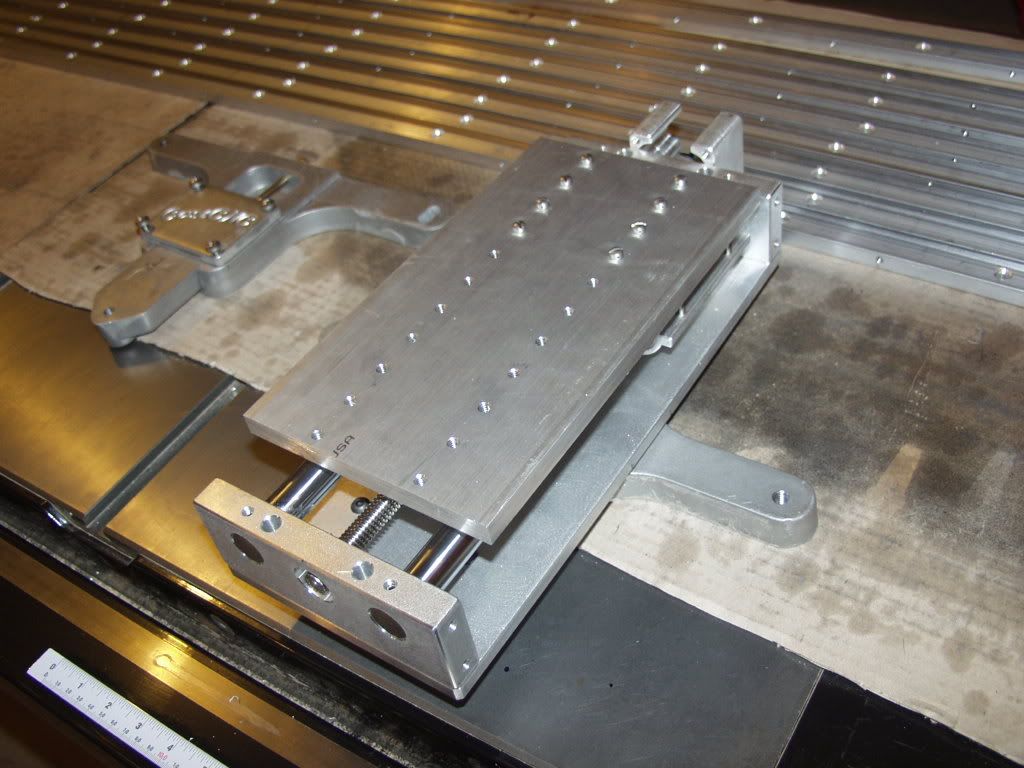

Tonights work was tapping teh holes in teh face and attaching the cast cnc covers and attaching the Linear Z from K2CNC the X front truck. I will post pictures tomorrow some time.

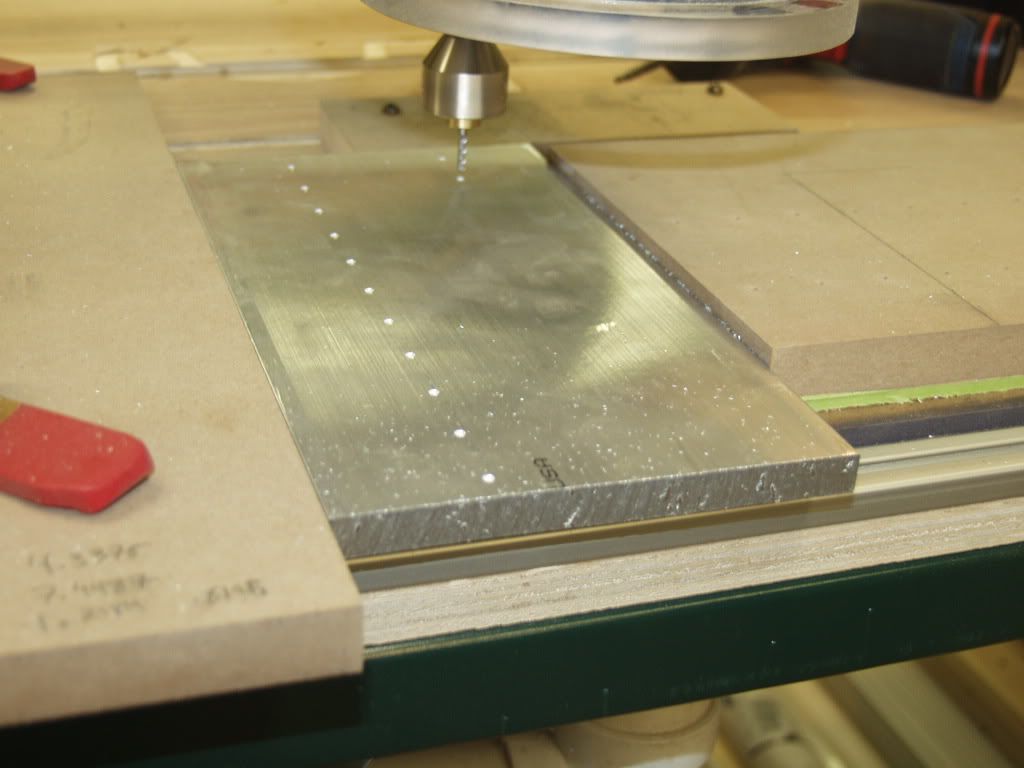

Also started marking up the edge of the X back truck. Tomorrow I will dust off the old Mark V Shopsmith and use the horizontal boring feature of that setup to drill the edges.

Glad its my shop I am responsible for - I only have to make me happy.

Reply With Quote

Reply With Quote