Got it. Thanks, Mike.

Still learning the wealth of this site.

Got it. Thanks, Mike.

Still learning the wealth of this site.

Carol in NV

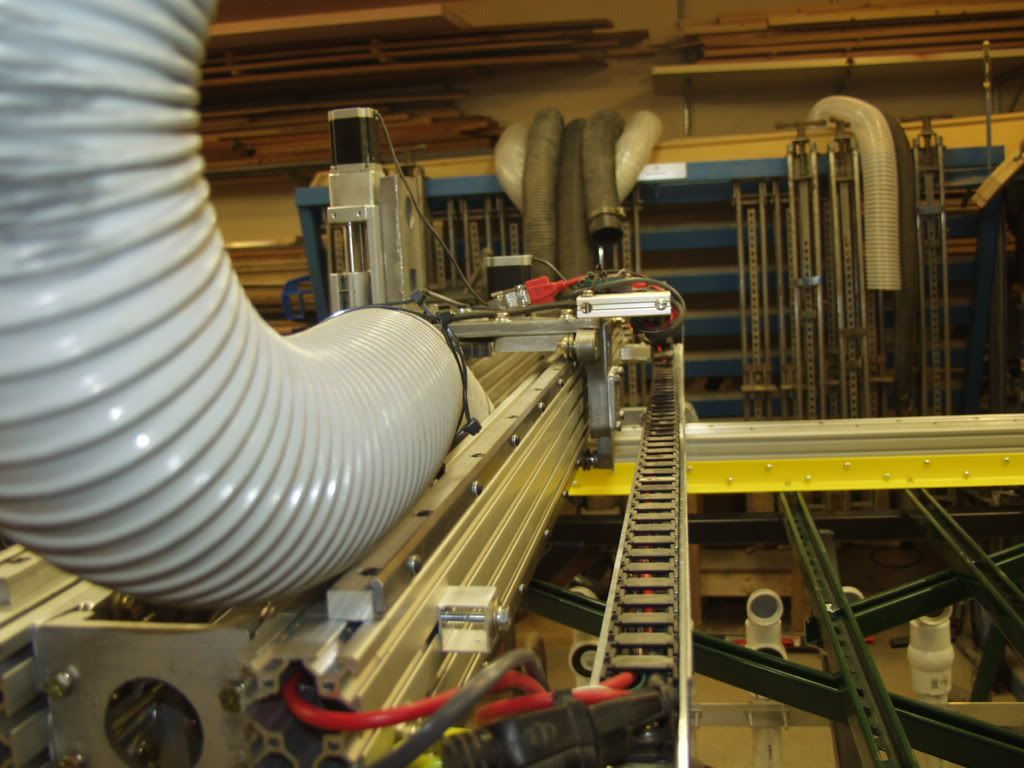

Tonight I mounted up the R&P plates on the Ys. I changed all the gears out too. I had a lot of wear on my MDF gantry setup - must not have had teh best contact.

Also mounted the echain angle alum and all the wiring and echain.

Should have the trucks under power tomorrow after drilling and tapping he R&P spring tension spots. Still have to do angle support too from the K2 to the rear of the X truck.

Glad its my shop I am responsible for - I only have to make me happy.

Well it is up and running. Looks like about 58" Y (had 62" before) and about 52-53" useable X (49" before) and 7.5"+ to unistrut - no table yet. It is soo nice.

Click here for crappy video

Youtube

http://www.youtube.com/watch?v=LInZPX3cDoE

photobucket

http://s39.photobucket.com/albums/e1...ike/Cast%20CNC

Glad its my shop I am responsible for - I only have to make me happy.

Your gantry exceeds the table width a bunch. Just a parking place for the Z axis? Planning a second Z axis and need the parking area?

Looking real good from here.

Carol in NV

The gantry is only about 1" on each side wider than it was designed for with Harry's Y carriage boxes. It gives you the ability to maximize the cutting area and still have room fir teh wide spaced upper bearings.

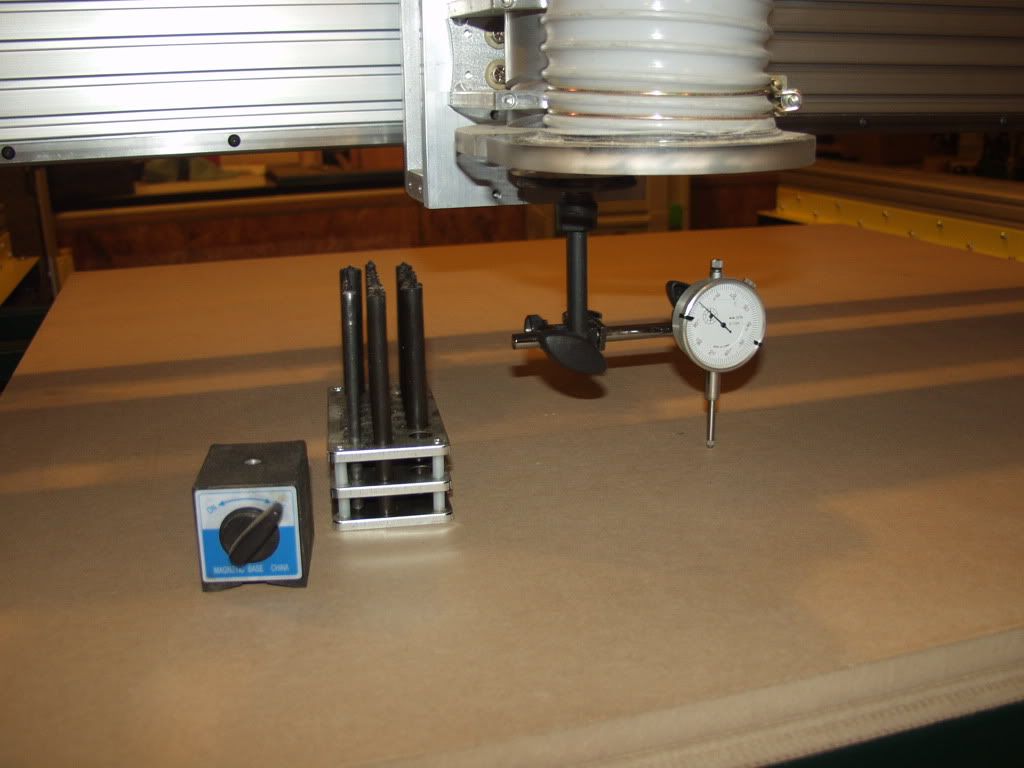

I do not own a tram so I used a 1/2" center punch and a HF dial indicator base and indicator. Had to drill out the adapter a bit but works just fine. Not bad for about $27 totals. Not sure how well it will work but I will give it a try. Glued together and attached two sheets of MDF to the bed tonight and will surface it tomorrow. A 3rd sheet will go on to of that bolted with nylon screws.

Glad its my shop I am responsible for - I only have to make me happy.

BTW - if anyone would like to build a Joes machine and does not want to do the work on the carriages (casting cleanup, drilling, tapping, etc) I am offering up those services. You will buy the castings from www.castcnc.com and Harry (owner) will ship me the parts and I will do the work and ship them back to you. His price is $590 for Joes members or $690 if you need to become a Joes member - all castcnc owners have a Joes membership.

I will prepare these carriages for use with nema 23 and nema 34 (offset drilled motor mount) and will work with Vrail or angle iron rails and will accept the 8" K2 Linear Z you will also purchase through K2 (Harry can help invoice that as well).

I will do the carriage work for $400 plus exact shipping charges.

I can also source the bolts and hardware for the carriages for you if you wish at an added expense. They will be grade 8 from farm and fleet.

I can also source the bearings for these carriages if Rick can supply them from Superior Bearing or from VXB if they ever come back in stock also at an added expense.

Both these options will add weight to shipping as well.

Otherwise I will provide a BOM of the parts you will need to purchase for these carriages and where to install them and in what order.

These carriages are meant for a Joes design using 25 S 5010 8020 X and Y axis extrusions with T2 Vrail on 3/4" X 1/2" aluminum bar stock or using 3/4" angle iron for rails. They may be able to be used on other 8020/rail setups but that is at your research and your risk - I will fit them to the Joes design I own.

These carriages also use the cncrouterparts rack and pinion kits and use 20 pitch rack from MooreGear.

You will also order an 8" K2 Linear Z for this design. Harry can assist you with invoicing that or you can buy it dorect from K2 yourself or through ebay.

Anyway, I am motivated to do some work to pay for the $6K in eye surgery I just had and thought I would offer up some castcnc milling services. Contact me if you are interested.

Glad its my shop I am responsible for - I only have to make me happy.

Mike,

Don't know if your still following this thread but I just finished reading most of it and found it very interesting. The CNC router bug bit me about 6 months ago. I ended up building one from the "buildyourcnc.com". More to see if I could do it than anything else. I am a woodworker of sorts and have a tool and die background but no electronics knowledge to speak of. Eventually I got it done without any big issues. Anyway it works and I love to play with it. I've made some signs that have turned out well. Of course as soon as I buildt it I started to see that it could be better. Specifically the one I made is structurally weak. So I have begun a bit of investigation about what else is out there. I'm amazed at all that is out there. So I ened up on your thread and was impressed with the cast design. I was also shocked to see that you live in Bloomington, Illinois. So do I!

To my point. I want to go ahead with another design at some point and I do like the cast idea, but given that I've already dropped more money that I thought I would on my existing machine, I hesitate to make a full fledged committment to something else. Maybe piecemeal is the way I have to go for now. Just purchase a little at a time and maybe it won't hurt so much. Given this, what would you suggest I do to begin with? I was thinking about buying the plans ($100) and go from there. Do you have any regrets or thoughts about what you might have done differently on your machine knowing what you know now?

Thanks

Dave from Bloomington (hot spot of DIY CNC)

David moving forward with another build will depend on what motors and controllers you purchased. I also built that machine about 4 builds ago. The only thing salvagable has been the electrics, which I have used on all my machines. However I had purchased a 4 Axis kit from CNCrouterparts.com.

The 4th Axis is used to give you dual drive on the Y Axis( or X depending on perspective) The dual drive is one thing that sets a quality build from a toy on a CNC router.

Other than the router no other part on your current build is salvageable. The good news is you did not spend much on those componets.

IF your electrics are up to snuff you will need to concider the following componets.

1. ACME lead screws and nuts or R&P system.

2. Rail System

3. Main beam components.

If you are building a 48" x 48" then forget the leadscrew option and goto R&P.

Thanks Michael S. I think the electronics are still OK. probably would need to go with larger motors so maybe a bigger power supply. I'm set software and computer hardware wise. Currently I'm thinking about Joe's CNC - cast version but its hard to know what the current "best in DIY class" design out there is. I don't really care to design my own machine. Even though I do like the design process, I would prefer to begin with the current state of the art rather than discover the art on my own.

My needs would be for furniture and sign cutting. probably mostly plywood, 2D cutting. Would like to have something that can take a decent cut using 3/8" to 1/2' bit and similar depths. Something that could give me maybe 50 inches/min or better or wouldn't take half a day to finish off a 4x4 piece of plywood. I've already burnt up one old router but I didn't think it would last too long.

Its great to know there are others that have already "been there". Thanks for sharing your stories.

Thanks Michael

Dave I am here and on Joes forum too. Was in Boston last week so sorry for the delay.

Tell us a bit more about your machine.

I was suprised to see that cncrouterparts site saying "nema 24" - its nema 23?? Anyway I am sure it is a typo.

You are more than welcome to come by sometime and see the scast machine in person if you want.

Glad its my shop I am responsible for - I only have to make me happy.