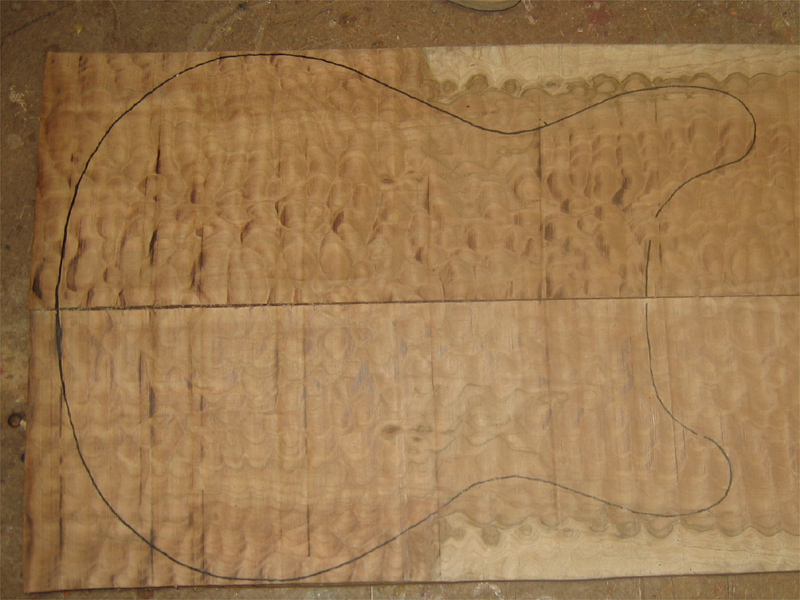

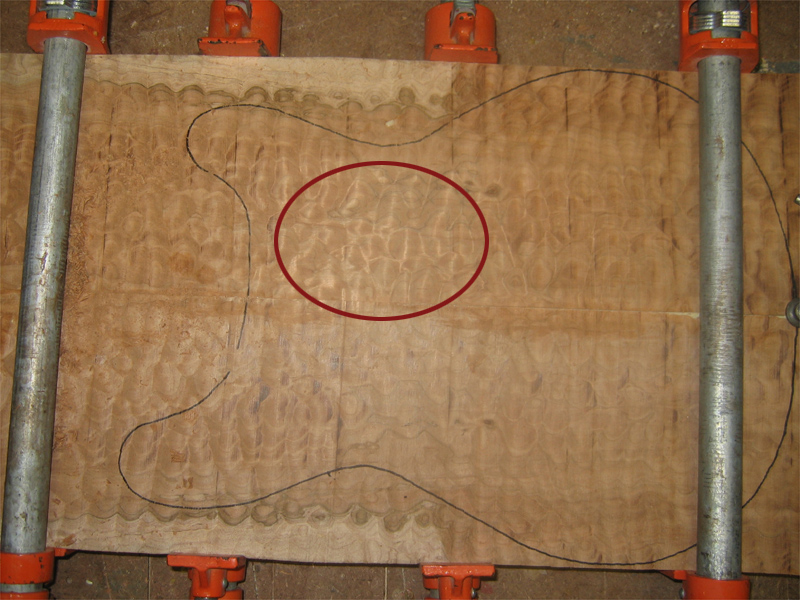

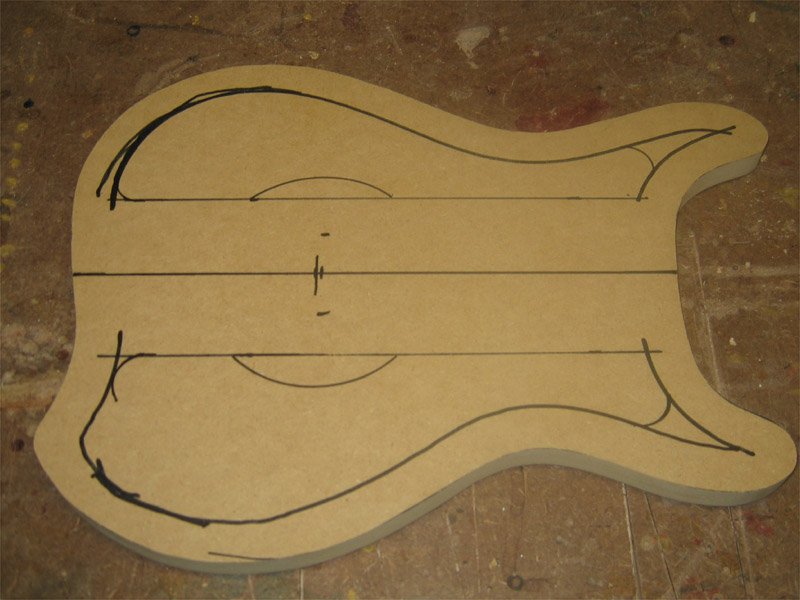

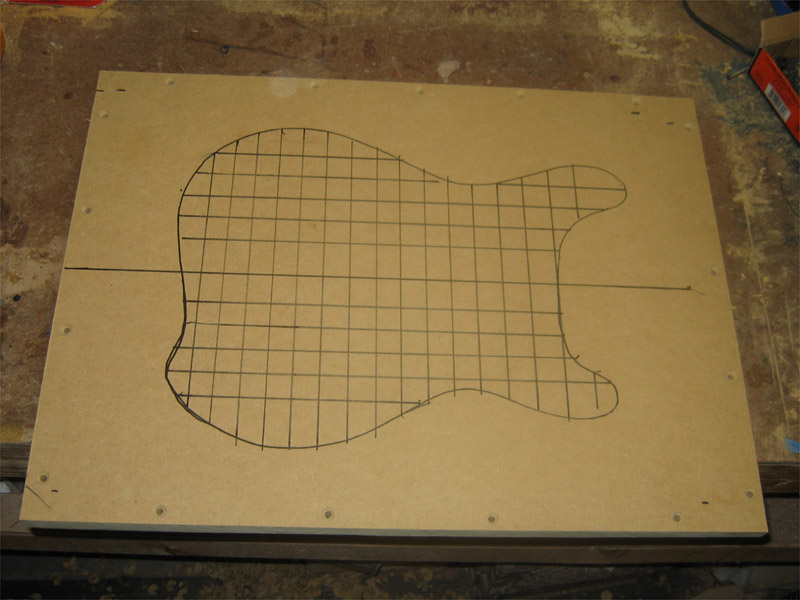

I'm really excited about this build. It's a design that I've been working on over the past few months. The body is inspired by a PRS but with a little different styling and wider, fatter horns. The top will be carved similar to a PRS but with a few twists. I'll have drawings completed and posted in the next few days.

Specs:

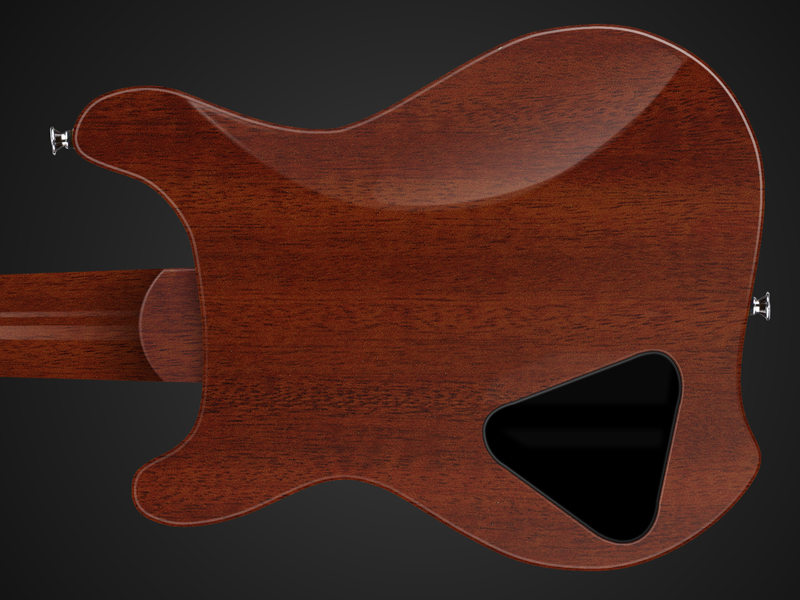

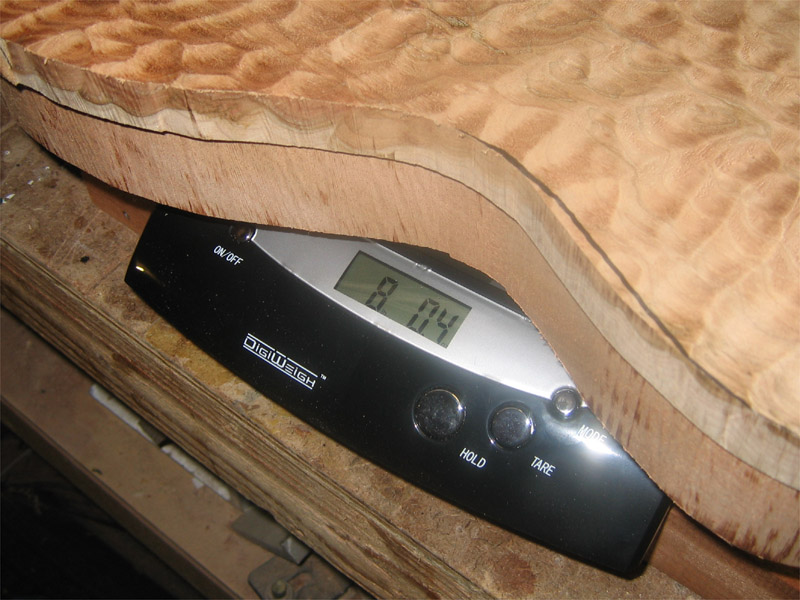

Peruvian mahogany body.

Quilted maple carved top with faux binding.

Peruvian mahogany neck.

Bolivian rosewood fretboard with quilted maple binding.

Dual HB...not sure which brand yet.

Wrap around bridge.

Volume, tone, 3-way toggle switch.

Peace,

Mark

Reply With Quote

Reply With Quote