Same here. Sure would like to find a fix.

Same here. Sure would like to find a fix.

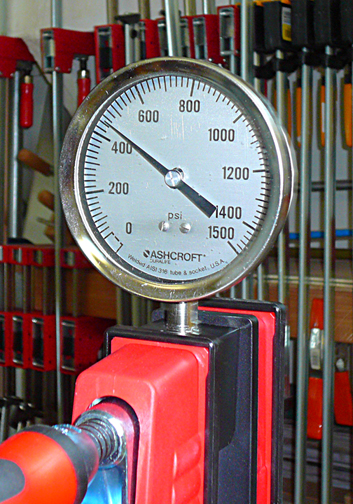

Joe, a basic pressure gauge... 1 sq inch surface area, reads in psi. This is total clamping force at the clamp only, not at the glue line.

As long as we're on the slippin' clamp thing, I have some K-clamps that work fine but I have some of these that slip in almost every position. I purchased four some time ago and three of them slipped so the the supplier sent me four more. Some of those now slip also.

Any fixes for these that anyone knows about??

I wish I had a solution for the slipping problem. Unfortunately, I think it would take a re-design of the clamp.... IMO, what is required is a rigid bar like we have now with hard metal, which is required to prevent bending...which under 30" clamps do a decent job at.... (but not the longer ones).... but the underside of the bar, where the movable jaw bites into, must be made of a softer metal.... soft enough to allow a better bite...but not too soft, where it will bite, and then deform the soft metal. This is clearly a difficult problem to solve in a $30 product....

Bar clamps with soft metal iron bars (not the polished nickel bars sold at Rockler) are the best "no slip" clamps you can use. In my tests, they loose 10% of force in 10 minutes...no other clamp has come close to this. I addition, due to their intelligent handle design, can produce 1000 - 1200 lbs of force with destroying your hands... that means one bar clamp is equal to 2 - 3 parallel clamps. There is no substitute for leverage, something not possible with thin round handles.

These iron bars are not glue friendly, as we all know, but they are the most effective clamps I have tested. Since I use fast dry glues, I simply re-tighten my parallel clamps every few minutes.... if I need epoxy type glues that require very long clamp times, I would probably invest in more bar clamps... I never tested them over many hours, its possible they too would start to slip, but I doubt they would slip as bad as the parallel clamps..

Jim, those look like Woodline's knock-offs, not K-Body clmaps. Similar though. I have some K-Body clamps from 5 months ago and they work just like the ones from 5 years ago. I know this certainly doesn't help those that are having problems but are the other folks reporting problems using Besseys or knock-offs?

The Bessey's use a threaded allen head screw for teeth; one engages the front edge of the rail and one engages the back edge. Perhaps one of these has fallen out? Here's a few shots from a clamp I have used weekly for many years:

K-body-teeth-002.jpgK-body-teeth-003.jpgK-body-teeth-004.jpg

As stated, none of mine are tight but they are all screwed in flush at the top, they can go deeper but appear to be sorta loose by design. If all surfaces of this screw are shot, it could be replaced. If the screw or the bar have been damaged, I would give some consideration my technique or the proper use of this clamp for the job. Don't get me wrong, I have many clamps that would fail if I used them for something that the K-body can do easily. There are other clamps in my arsenal that can provide that crushing power if required. The K-bodys are good to around 400 or 500lbs IIRC. HTH.

Last edited by glenn bradley; 02-20-2010 at 3:25 PM.

"A hen is only an egg's way of making another egg".

– Samuel Butler

> The K-bodys are good to around 400 or 500lbs IIRC. HTH.

Glenn, this is about right.... although I have gotten some well tuned Bessyes up to about 750 lbs, its painful to the hand...and this is with some extra heavy duty thick overgrips. While 500 lbs seems like a lot of force, it's only 1/2 the amount advertised by Bessey, nonetheless a decent amount of pressure. But remember, if you divide this over a glue area of 10 sq inches, (2" thick boards over 5" between clamps) its only 50 psi at the glue line. So the simple solution, when more clamping pressure is required, is to use more clamps, vs. "pushing" less clamps...... as the less you "push" the clamps, the less they slip, so that is two good reasons not to back down... (less slippage and easier on your hands )

My guess is, clamp makers all try to win the advertising war.... and max. clamping pressure "psi" is always a buzzword, just like MegaPixels in digicams....however, I have never seen a clamp maker advertise slippage at x psi, over 2 minutes, 4 minutes, 10 minutes, etc. This specification is more relevant to how the clamp should be used......

Oh, forgot to mention.... I have tested the Woodline copies of the Besseys and immediately returned them... .while the Revo's are far from a perfect clamp (max pressure and slippage), the Woodlines were much inferior.

BTW, I am not picking on Bessey.... Gross Stabil clams were nearly 2x worse than Besseys...and Jets did not perform much better.... And despite what appears as "shortcomings", all in all, for the money we pay for these clamps, you are getting a quality clamp, with the Stanley's leading the pack (in the parallel clamp category, but I like the option of ganging Besseys together for a longer clamp)

As for the thread issue, I have had a few of these as well.... the max pressure the clamp will produce, is partly dependent on the frictionless contract between the threads. some threads are machined better than others. These threads should be kept lubricated to reduce friction.... some new clamps I test of the same make and model, will show variances from, none, to 150 lbs... this is mainly due to the thread friction. Often just adding some teflon lubricant, will increase the clamps output by 150 lbs. (when the threads were dry) The last batch of Revos were fully lubricated from the factory... maybe they have been reading these threads... ;-)

Many of my Bessey clamps also slip, which makes using them difficult to use. What about the Jorgensen version of the K - Bodies?

Glenn,

I said, I do have Bessey's that do not slip, but, these (the one pictured) do.

I thought maybe someone had a cure for the problem.

Thanks,

Jim

Since this subject was brought up again.... yesterday, I decided to test a new batch of Revo's for slippage..... I tightened to 600 lbs.... I wanted to check the 10 and 15 minute levels...but never made it back into the shop, this morning, the gauge read 30 lbs, about 24 hrs... for those who work with long cure epoxies, this might be valuable information....

Will,

Just curious, but are you sure that the pressure reduction that you're seeing is the clamp slipping and not a problem with the gauge? Are you able to tighten the clamp to the original indicated pressure after it has decreased without releasing and re-tightening the clamp?

John

I have a few of the older Bessey's and a few Revos, but have not used them on more than a few projects. I was considering changing to Jet's because I heard they were better. But, based on what I am reading in this thread, that may not be the case. Recently I was told that the Jorgensen 6000 (old style) clamps were the ones to use when you really needed significant pressure like clamping large pieces of 2 inch stock. Has anyone used these? How do they compare with the others?

> Just curious, but are you sure that the pressure reduction that you're seeing is the clamp slipping and not a problem with the gauge?

When I run this same experiment with a pair of vice grips, there is virtually NO pressure loss... the gauge is quite simple, its not failing....

> Are you able to tighten the clamp to the original indicated pressure after it has decreased without releasing and re-tightening the clamp?

Yes, of course..... that is why I constantly re-tighen every few minutes during a 20 minute glue-up.... unless you have clamps that don't slip, then this should be considered mandatory....

> But, based on what I am reading in this thread, that may not be the case. Recently I was told that the Jorgensen 6000 (old style) clamps were the ones to use when you really needed significant pressure like clamping large pieces of 2 inch stock.

I only have a few Jorgensens.... they perform as well as the K Bodies, maybe a bit better.... as mentioned, and I know its a hard pill for many of us to swallow, but if you want to use parallel clamps (vs. bar clamps) and you want max. pressure, nothing comes close to the Stanley Baily's..... they nearly double the force of the all the big name clamps... and....they slip the least.... here is a Stanley after 4 hrs, it started at almost 1200 lbs.

BTW, I am not the only one who found this little gem, a few of the ww magazines also tested them and agreed in general with my findings. And whats really strange is, they are no longer on Amazon, they only sell the "F" Bailey clamps now? About a year ago, "Big Lots" stores were blowing out the Bailey Parallel clamps for $10, if there was one local, I would have cleaned them out :-) I thought Stanley was closing out the line of parallel clamps....but I see them on the Sears web site... (full price) so I guess not......

http://www.stanleytools.com/default....lel+Bar+Clamps