Ok, I've searched for this but haven't found much - perhaps because I might be crazy for wanting to do this.

I have a nice log of black walnut that is laying down in some woods next to my house. It's about 8-10 ft long and 18in diameter. It's straight with no branches.

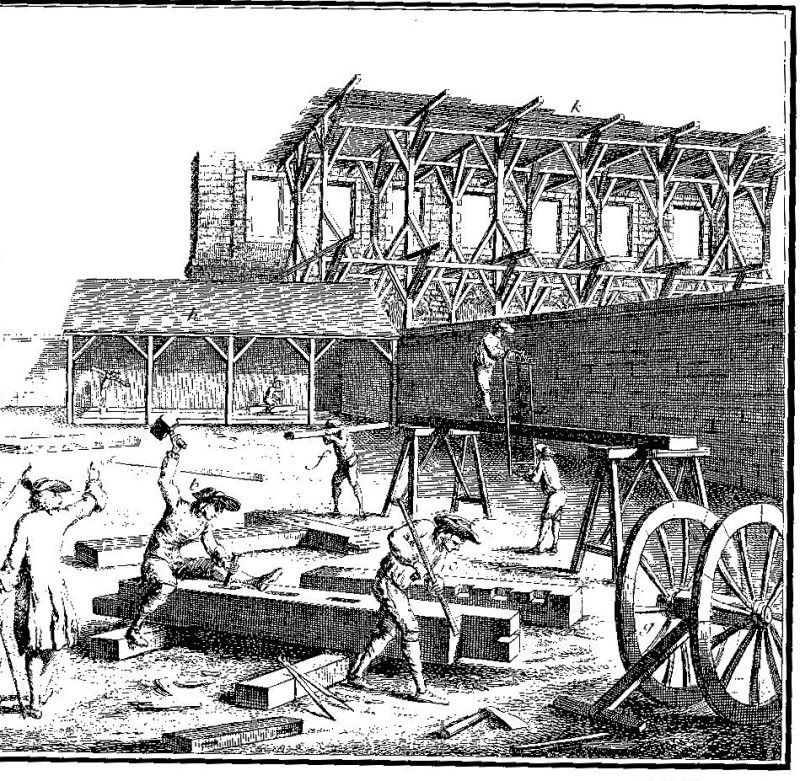

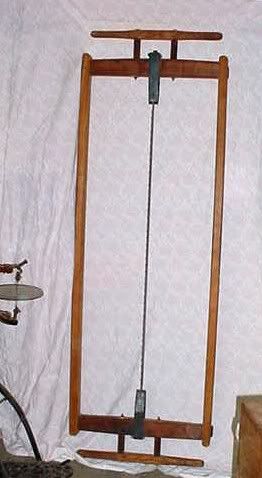

My question is: what is the best way to get this thing sawn into 4/4 plainsawn planks for making some furniture? The kicker is I want to do this all by hand. I'm not afraid of hard work and realize that is what it is going to take. I just want to know the proper way of going about this project.

Thanks!

Reply With Quote

Reply With Quote

Jr.

Jr.