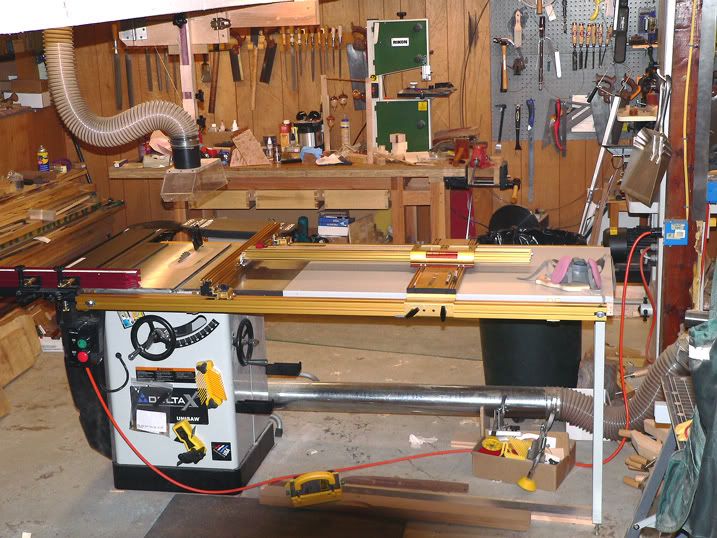

I need to build a permanent (non folding) tablesaw outfeed table for my Unisaw, and would like to utilize the space below for storage, either drawers or shelves. I'm thinking about 5 feet wide, and 30" deep. The 30" depth is about as much as I would want to encroach upon my workbench. The extra width would allow me to use it for assembly as well.

I thought about a folding option, but it seems it would always be in the way if I needed to get at whatever was stored underneath, and I REALLY need convenient storage space. I might consider a folding section directly in front of the saw table (minus wings), which could be utilized if the need would arise, and would only compromise a portion of the storage space.

I don't have much experience with designing this sort of thing, so pictures showing support/storage details would be most helpful. Thanks.

Dan

Reply With Quote

Reply With Quote

Those who dream by day are cognizant of many things which escape those who dream only by night

Those who dream by day are cognizant of many things which escape those who dream only by night