Someone requesting an OWT (Old Womans Tooth) router plan came up on Traditional Tools, This simple Tutoral is how I make mine.

I thought I would post over here too.

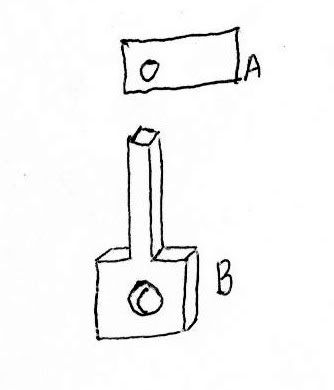

Mini or Thumb Router.

I prefer a couple of upright handles to just a place for the thumb and fingers to grasp the tool.

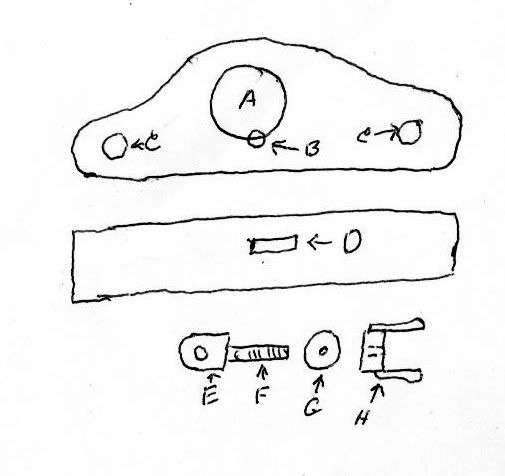

1. I start out by sawing out a blank after deciding where to drill the holes.

2. Then I chop the mortise "D" for the retainer, usually 1/4 by 1 inch.

3. Next I mark the hole "A" with the bit, normally 2 inch diameter.

4. Drill hole "B" centered on the OD of hole "A" and in the center of Mortise "D". Hole "B" is the cutting tool bed.

5. Now Drill hole "A" usually with a Forstner bit.

6. Then I drill holes"C" usually 1 inch and 1/4 inch deep for the handles which will set in these and have a brass screw from the bottom to secure them.

7. I round over all the edges a bit, and use Danish oil on the body.

8. I next make the keeper "E" out of 1/4 by 1 flat and drill hole "F" 1/2 inch in diameter, and weld on a piece of 1/4 inch all thread to tighten it with.

9. Washer "G" goes on next.

10. The retaining Nut "H" shown is the most common retainer I have seen on the antique ones I have repaired for others, but I prefer to use a hand forged rams horn Wing Nut on mine.

Jr.

Jr.

Reply With Quote

Reply With Quote