I've been considering converting an old lathe to do/be what I want, but building a larger lathe--primarily out of wood--with variable-speed seems like the wiser approach (and maybe cheaper in the long run).

Here's a link to something like what I'm considering

And here's another

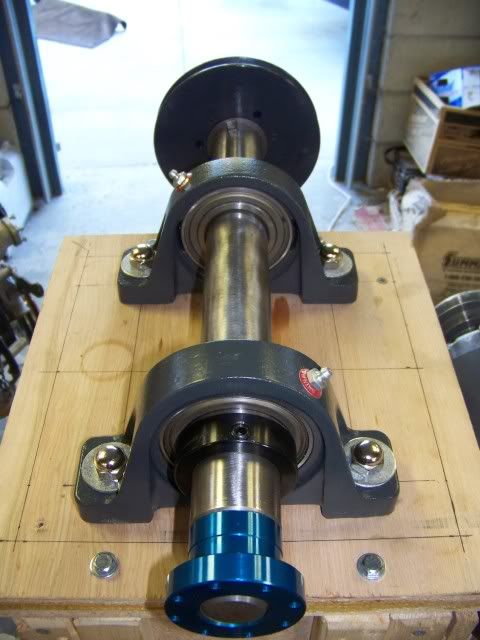

Is there someplace I can buy a fully-machined headstock spindle

that will accommodate current standard components.

Specifically, I'm thinking:

a) 1" diameter shaft

b) Maybe 12" long

c) Center drilled

d) MT #2 taper (both ends?)

e) 1"x8 TPI RH on the bed end, and 1"x8 LH on the outboard end

I'm assuming there are step pulleys and plate bearings readily available for the 1" diameter shaft.

Please tell me if I'm wrong about that; if some other spec is standard.

Of course, I also need to come up with a suitable tailstock spindle that is threaded externally for ram travel. I figure center-drilled with an MT#2 taper is a must. I'd appreciate any suggestions for a source.

Or if anyone has a complete tailstock pulled from an old machine that I could adapt, I'd gladly consider buying one that's sturdy enough and in good working condition. Even a metal lathe tailstock might work...

Thanks,

Tom

Reply With Quote

Reply With Quote

.

.