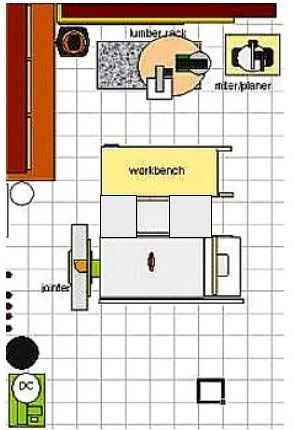

I'm finally moving from an apartment to a small house with a garage. Unfortunately, I need to share the space with the car so of the 10' x 23' garage, all my woodworking tools will need to collapse into a 10' x 9' space. I'd like to fit a 10'' European-style jointer/planer, a 16-17'' bandsaw, and a table-mounted drill-press. For everything else, I'll be using hand tools. Other than roll-away stands for the machines and roll-away cabinets for everything else, does anyone have any tips for laying out a space this small? I usually fell and air dry wood about 200 kms away so my wood storage requirements are (thankfully) minimal. I don't plan on using the machines without the car out, the door open and a portable dust collector. I've accepted that I'll need to put my 30'' x 6' workbench against a wall, but I'd really like to maintain access to it (even when the car is in the garage).

Reply With Quote

Reply With Quote

(no cars!

(no cars!  )

)