I have just started making some drawers and boxes. I'm playing with all the methods (box joint, dovetail, drawer lock, miter and lock miter, etc.)

Lately I have been working with this drawer lock bit:

r01840v7.jpg

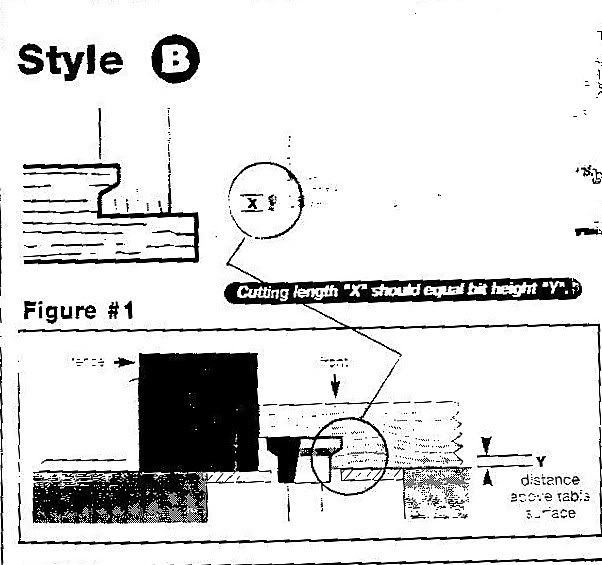

I didn't find an insturction page for the bit on the Bosch website, but I found one at Rockler for a smaller diameter bit of the same design. (there are two 'drawer lock joint' bit designs on the market)

http://www.rockler.com/tech/53810.pdf

I understand to set the fence to get the reveal for the drawer front lip, But I am having some issues with setting the bit height. Is it my imagination or is there only one bit height for this bit that gets a tight fit?

Reply With Quote

Reply With Quote

Jr.

Jr.