I am currently working on design for a stand for my DW-735. It is getting too heavy to carry 1/2 way across the shop. What were the solutions for you all? Pics very helpful! Thanks alot and Happy New year!

I am currently working on design for a stand for my DW-735. It is getting too heavy to carry 1/2 way across the shop. What were the solutions for you all? Pics very helpful! Thanks alot and Happy New year!

Here's mine naked: http://www.sawmillcreek.org/showthre...d=5960&t=91236

and here it is in use: http://www.sawmillcreek.org/attachme...9&d=1177997813

Do a Google search here on 'flip top'. You will get a bunch of hits.

Last edited by glenn bradley; 12-31-2008 at 10:46 PM.

"A hen is only an egg's way of making another egg".

– Samuel Butler

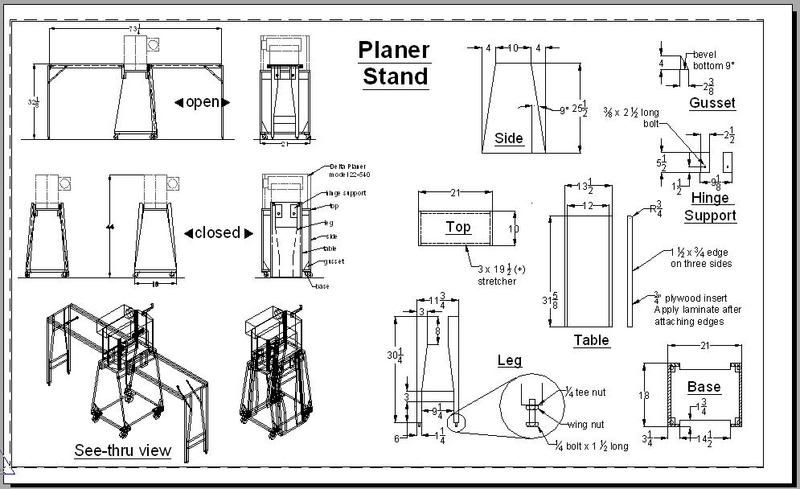

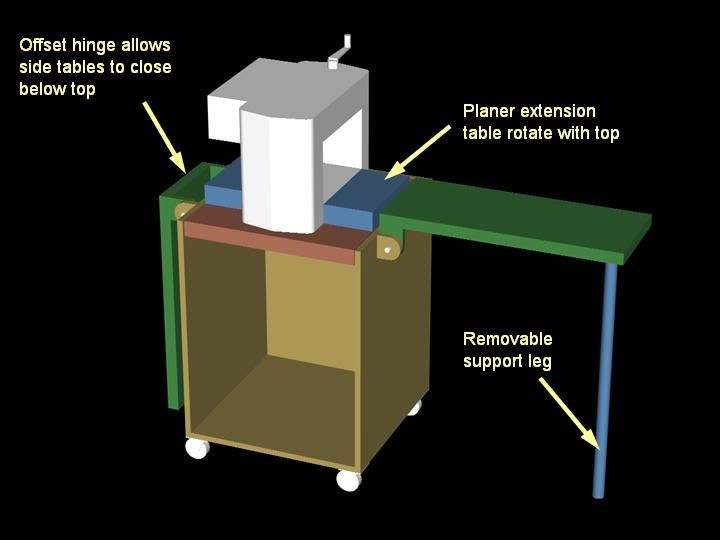

Here's some pics of my little planer. It's a different model than yours, but the idea is the same. The best part is the rock solid infeed and outfeed tables that fold neatly away. Also, when the tables are folded down, they don't obstruct the pathway when short boards are fed.

By the way, I agree that these planers are not very portable (anymore).

-Jeff

A little more info...

Not a flip top, but I made the one from the plan available from WOOD Magazine, January, 1995 - Issue #76. I really like it and it's been hanging around my shop for about 10 years now.... I had to customize a little to fit my planer. Probably the only reason I haven't bought a new planer - this set up works just fine. Here's a link to the plan.....

It's portable too. Has some casters on one end....

Not really a good picture, but it's the only one I could dig up....

Last edited by Ed Sallee; 01-01-2009 at 10:28 AM.

I think you can build one as nice as you want, Jeff's is really nice and I wish I had the room for one like that.

I made mine really cheap and just used 2x4s and a length of 3/4 pipe for HD. It does everything I need it to do, rolls under the bench out of the way.

http://www.sawmillcreek.org/showthre...ghlight=ridgid

Here's mine.

I put my DW735 on a Delta planer/miter saw stand. I do all of my planning in the driveway so this method lets me keep my planer standing on end like a hand truck when it's in the shop, it's easy to move out to the driveway, and just a tug lifts and latches it in the up position. I also like the extendable roller guides that allow placing a support roller about 3 1/2 ft away from each end of the planer. Mounting the planer on this stand requires a 3/4 plywood adapter, but this only took me about a half hour to make and install.

Charley

The rub with the DW735 for this kind of thing is that it's a very, very heavy machine compared to most of the other portable planers. The setup that Jeffery shows might be a better solution for this heavy machine, IMHO.

--

The most expensive tool is the one you buy "cheaply" and often...

Jim is of course correct--the DW735 is a heavy machine. But when I had one, it sat on a flip-top stand which was very stable and which also housed a Makita 10" SCMS.

I don't have very good pictures, unfortunately. I need to get better about that. It was one of the first stands I made for the shop--totally out of necessity, as I didn't want to work on the floor. I based the design off someone else's plans I found on the web. Unfortunately, the URL doesn't seem to be working anymore and I don't want to post someone else's material. If you PM me with your email address, though, I'll send along a .pdf.

Here is what my stand looked like. You can see the sides are double-thick 3/4" ply, and the top has several 7/4 - 8/4 pieces in it. I eventually made a drawer for the bottom opening to house accessories before I sold both the planer and the saw earlier this year.

If you do go with a flip top, I recommend incorporating fold-up extension tables for added ease, stability and snipe reduction. This feature was just discussed in a flip top about a week or so ago. Here was one suggestion...

-Jeff

Recent discussion here:

http://www.sawmillcreek.org/showthre...highlight=flip

Dewey

"Everything is better with Inlay or Marquetry!"

Happy New Year everyone! Those are all excellent ideas! I will continue working one my idea. I like he idea of using black or galv pipe for the pivot cheap and strong. I never thought about it, but I should probably think about incorporating infeed/outfeed wings. Awhile ago I got an AutoCAD file from a Creeker but I can't find (or remember) who it was. Anyone remember this posting?

Not a flip-top, but pictures of my DeWalt 735 and stand here.